Cold gas spraying

Cold gas spraying

MAXIMUM ADHESION, MINIMUM HEAT

Unique solutions need unique partners. obz innovation gmbh is the most frequently chosen development partner for functional coatings using cold spraying.

COLD GAS SPRAYING

COLD GAS SPRAYING

MAXIMUM PERFORMANCE AT LOW TEMPERATURES

Cold spraying is an innovative process for surface finishing that is characterized by the use of low temperatures. In contrast to conventional spraying processes, which require high temperatures to melt the coating material, cold gas spraying processes the material in a solid state. A high-velocity gas hurls the powder onto the surface of the component at enormous speed. The kinetic energy is so high that the particles deform plastically on impact and bond firmly to the surface.

YOUR ADVANTAGE

"Cold gas spraying and thermal spraying are a clean and chemical-free alternative that produces excellent coatings, whether for wear and corrosion protection or electrically conductive coatings. Together with the environmentally friendly process, this leads to a positive ecological balance!”

Max Fabig

Application Development, Materials Science / M.Sc

SPECIAL FEATURES OF COLD SPRAY COATINGS:

- Low oxide content

- High density

- High thermal and electrical conductivity

- Generation of compressive stresses

- Minimal heat input into the substrate

- Dense microstructure

- Stable phases and material composition

- Minimal grain growth, nanocrystal structure is not changed

Optimum coating properties thanks to cold gas spraying

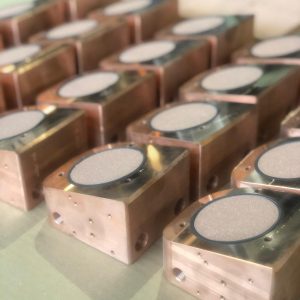

Thanks to the low process temperatures (150-1000 °C), the structure of the coating material remains virtually unchanged, which is particularly advantageous for materials that tend to oxidize at high temperatures. For example, aluminum can be coated with copper layers in such a pure, low-oxide form that they achieve up to 90 % of the thermal and electrical conductivity of pure copper. These properties make cold spray coatings particularly efficient, for example due to their excellent electrical and thermal conductivity and the ability to create stable and dense microstructures.

Areas of application

Areas of application

Flexible and precise for demanding applications

Cold gas spraying is used in numerous industries, from electronics to aerospace and the automotive industry. It is used to coat sensitive materials that could be damaged by high temperatures or for highly wear-resistant surfaces. The ability to generate compressive stresses and the low heat load on the substrate help to preserve and improve the mechanical properties of the base material.

Cold spraying is the spraying technique of choice when it comes to coating materials that could be damaged by high temperatures. Low oxide content with high density and high thermal and electrical conductivity are just some of the advantages. A dense microstructure, minimal grain growth with an unchanged nanocrystal structure are certainly others.

Your contact person

Fabian Trenkle

Head of Research and Development / Dr.-Ing.

Your contact person

Fabian Trenkle

Head of Research and Development / Dr.-Ing.

RESULTS

RESULTS

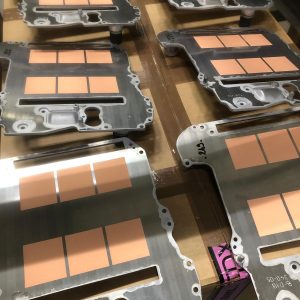

COLD GAS SPRAYING IN USE

Cold gas spraying is in constant use at obz innovation gmbh. The result is impressive surface solutions for a wide variety of applications.

Complete production

Complete production

OUR COMPLETE PRODUCTION SOLUTIONS

OUR COMPLETE PRODUCTION SOLUTIONS

Complete production with the use of turning, grinding and milling optimizes the entire production process. This ensures maximum efficiency and quality and enables us to take individual customer requirements into account.

SPRAYING PROCESS

SPRAYING PROCESS

OUR INJECTION PROCESSES AT A GLANCE

Get an overview of our spraying processes. Whether cold gas spraying, thermal spraying or suspension spraying – we have the solution for maximum surface performance.