Mechanical processing

Mechanical processing

FINISHING TOUCHES FOR YOUR COMPONENT

obz innovation gmbh processes your component mechanically until final completion

Mechanical processing

Mechanical processing

PRECISION AND FLEXIBILITY

Machining is an essential part of our manufacturing solutions and covers a wide range of processes, including grinding, turning and milling. Our state-of-the-art machinery is designed to meet all requirements precisely and efficiently. With the use of the latest manufacturing technologies and a team of highly qualified specialists, we guarantee outstanding quality, fast production times and consistently high machining accuracy.

The requirements for sprayed coatings are extreme – as is the precision of the subsequent mechanical processing. This is the only way to ensure the functionality and performance of the coatings. We not only process the spray coating, but are also able to manufacture complete components according to your specific requirements. This guarantees unrivaled flexibility and an almost infinite variety of applications.

YOUR ADVANTAGE

"obz innovation gmbh is your ideal partner for mechanical processing. Whether individual parts or series components, our qualified employees and modern machinery guarantee optimum quality and efficiency.”

Felix Wüst

Application Development / B.Eng.

PRODUCTION SOLUTIONS FOR EVERY REQUIREMENT

PRODUCTION SOLUTIONS FOR EVERY REQUIREMENT

OUR MACHINERY

5-axis-machining-center

Model

OKUMA MU-500VA-L

Special features

- X = 1.250 Y = 660 Z = 540

- C-axis rotatable

- 5-axis simultaneous operation

- Ø 730 mm x 500 mm

- component weight: max. 500kg

- rotary table

- 15 KW n = 1.000 1/min

- milling spindle

- 22 KW n = 50-12.000 1/min

CNC lathe

Model

Bickenbach ST200

Special features

- max. Ø 284 mm L = 406 mm

- hydraulic chuck

- vacuum chuck

Model

Okuma Genos L300E

Special features

- max. Ø 300 mm x L 1.000 mm

CNC Cycle lathe

Model

Special features

- max. Ø 520 mm L = 1.500 mm

Internal cylindrical grinding machine

Model

Special features

- max. Ø 650 mm x L 650 mm

External cylindrical grinding machine

Model

Special features

- max. Ø 520 mm x L 1.000 mm

Cylindrical grinding machine

Model

Okamoto OGM-350 UNC III

Special features

- max. Ø 300 mm x L 500 mm

- max. workpiece weight between centers = 150 kg

Model

Okamoto OGM-390 UNC III

Special features

- max. Ø 300 mm x L 900 mm

- max. workpiece weight between centers = 150 kg

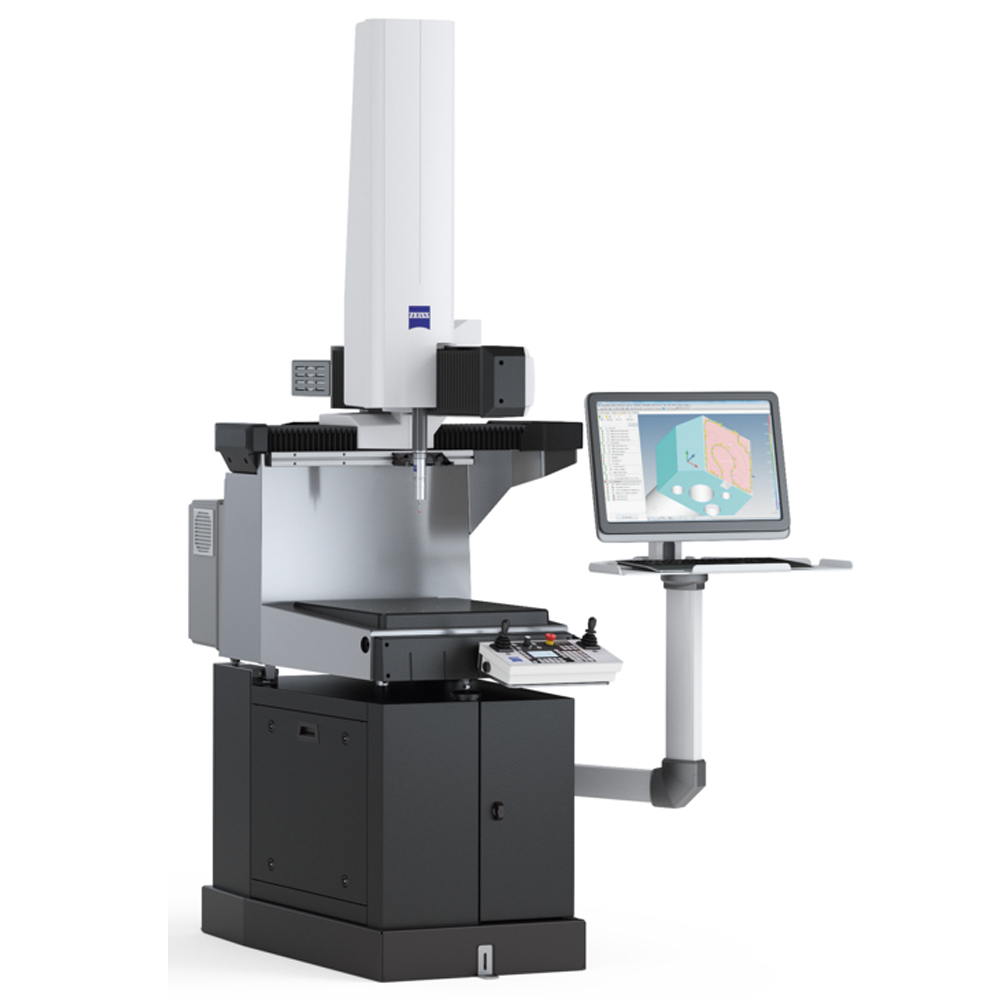

3D coordinate measuring machine

Model

ZEISS DuraMax HTG

Special features

- X = 500 mm Y = 500 mm Z = 500 mm

- Low length measurement deviations

- Exchangeable table with 25mm diameter for optimum reproducibility

Model

Mitutoyo CRYSTA-Apex S9106

Special features

- X = 700 mm Y = 1.000 Z = 600 mm

- Low length measurement deviations

- Integrated thermal error compensation (16°C to 26°C)

Surface grinding machine

Model

ELB-SCHLIFF SWH 4 ND

Special features

- Grinding length: 450 mm

- Grinding width: 200 mm

- Workpiece height: 400/460 mm

- Table load: 250 kg

Tangential grinding machine for flat surfaces

Model

Delta LC 400

Special features

- Largest grinding surface: Ø 400 mm

Your contact person

Sylvain Badie

Plant Manager / Dr.-Ing.

Your contact person

Sylvain Badie

Plant Manager / Dr.-Ing.

RESULTS

RESULTS

PRECISION IN DETAIL

Experience the variety and precision of our mechanical processing. From complex components to machined surfaces – our expertise and state-of-the-art technology ensure results that meet the highest standards.

CONTRACT MANUFACTURING

CONTRACT MANUFACTURING

CUSTOMIZED PRODUCTION SOLUTIONS

From innovative spraying processes to mechanical machining – our comprehensive manufacturing processes and technologies are also available as individual services for contract manufacturing.