THERMAL SPRAYING

THERMAL SPRAYING

RESISTANT COATINGS

THERMAL SPRAYING

THERMAL SPRAYING

EFFICIENT SOLUTIONS FOR HIGH-PERFORMANCE SURFACES

Thermal spraying is a proven process for surface finishing. Coating materials are accelerated and melted onto the substrate. This creates durable, high-performance coatings that meet the needs of a wide range of industries. Thermal spraying makes it possible to adapt surfaces to specific requirements, such as wear resistance, corrosion protection and thermal conductivity. The process opens up a wide range of possible applications and offers solutions for complex challenges.

Atmospheric plasma spraying

Atmospheric plasma spraying is a thermal spraying process that works with high flame energy and temperatures; the coating material is used exclusively in powder form, which enables targeted and uniform layer formation.

Advantages

As a rule, a high coating quality can be achieved, especially with high-melting and ceramic materials. The flexibility in material selection makes atmospheric plasma spraying a preferred option for demanding applications.

Spray materials

A variety of spray materials are used, including spray wires, powders for flame and plasma spraying as well as self-flowing alloys and ceramic spray powders.

Areas of application

Areas of application

Atmospheric plasma spraying is widely used in the aviation industry, for example in the construction of high-quality coating systems for aircraft engines, as well as in the manufacture of components for textile machines, printing machines and pumps.

Triplex Pro plasma spraying

Triplex Pro plasma spraying uses an innovative 3-cathode technology that generates three independent arcs. This enables a stable plasma flame over a wide range of gas flows, gas mixtures and pressures.

Advantages

The process is suitable for all powder materials and offers high throughput rates, a significant increase in productivity. Thick and dense coatings can be produced, while stable and reproducible results are guaranteed.

This makes Triplex Pro plasma spraying a powerful solution for applications that require precise and durable coatings.

High velocity oxygen fuel spraying (HVOF)

High Velocity Oxygen Fuel (HVOF) is a process characterized by the combustion of flammable gases and the acceleration of these gases in a nozzle. The powder particles are accelerated to speeds of up to 800 m/s while they are partially melted in the flame.

Advantages

The process produces dense coatings of high quality and ensures excellent adhesion of the coatings to the base material. The process can be carried out safely and reliably.

Areas of application

HVOF is used in the production of electrical and thermal insulation coatings, corrosion protection and general wear protection.

Powder flame spraying

Powder flame spraying is a universally applicable, cost-effective spraying process (UNI-SPRAY-JET / MINI-SPRAY-JET) that works exclusively with spray additives in powder form.

Advantages

The process enables the processing of almost all filler materials, including ceramics and plastics. It can be operated without compressed air and requires only low investment costs. This makes it an attractive option for many applications.

Areas of application

Powder flame spraying is widely used in the production of repair coatings, corrosion protection and general wear protection.

Wire flame spraying

Wire flame spraying is a cost-effective process for the production of metallic coatings in which the spray filler material is used exclusively in wire form.

Advantages

All sprayed particles are completely melted, resulting in a high application efficiency. These properties make the process particularly effective and economical.

Spray materials

A wide range of materials are processed, including various carbon, chromium and nickel-chromium steels, bronze, zinc, copper, molybdenum as well as nickel and nickel-aluminum.

Areas of application

Wire flame spraying is often used to repair worn machine parts, provides corrosion protection and ensures effective wear protection with molybdenum.

Arc Spraying

Arc spraying is characterized by a high application rate. The spray filler material is used exclusively in the form of electrically conductive wires.

Advantages

With deposition rates of over 20 kg/h, this process enables rapid processing and at the same time offers good coating adhesion. The operating costs are low and very rough coatings can be produced that are suitable for various applications.

Areas of application

Arc spraying is often used for repair and wear protection as well as for corrosion protection on large components or thick coatings of more than 1.0 mm.

Your contact person

Sven Hartmann

Managing Director / Dr.-Ing. M.A. MBA SFI

Your contact person

Sven Hartmann

Managing Director / Dr.-Ing. M.A. MBA SFI

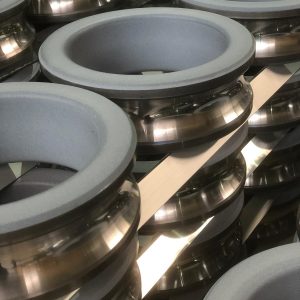

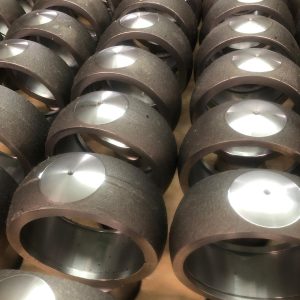

RESULTS

RESULTS

CONVINCING RESULTS

We use our expertise in thermal spraying in numerous projects. State-of-the-art spraying techniques produce high-performance coatings that meet the highest requirements of a wide range of industries.

Complete production

Complete production

FROM THE IDEA TO THE FINISHED PRODUCT

With our complete production, we offer you an efficient and flexible solution for the entire production chain. This not only enables cost savings, but also a faster market launch of your products.

SPRAYING PROCESS

SPRAYING PROCESS

EVEN MORE INFORMATION ON THE SPRAYING PROCESSES

Our innovative spraying processes offer a wide range of benefits and application options. From cold gas spraying to thermal spraying and suspension spraying – find the solution that best suits your requirements.