Thermal Spraying technology

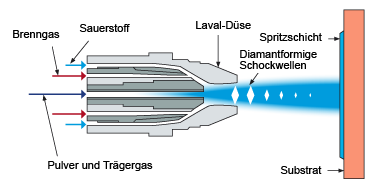

High velocity oxy-fuel spraying (HVOF)

High velocity oxy-fuel spraying (HVOF) Characteristics:

- Combustion of flammable gases

- Acceleration of gases in a nozzle (HVOF = High Velocity Oxygen Fuel)

- The powder particles are accelerated to very high velocities (up to 800 m/s)

- Powder partially melts in the flame

Advantages:

- Dense coatings

- High quality coatings

- Excellent coating material connection

- Reliable process

Application:

- electrical and thermal insulating coatings

- Protection against corrosion

- Protection against wear

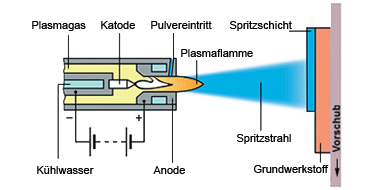

Atmospheric plasma spraying

Atmospheric plasma spraying Characteristics:

- Spraying technology with high thermal energy and high temperature

- Only spraying material in powder form usable

- High investment costs and operating expenses

Advantages:

- High coating quality achievable, especially suitable for highmelting-point materials, primarily ceramics

Material for thermal spraying:

- Spray wires

- Spray powders for flame- and plasma spraying

- Spray powders for HVOF spraying

- Self fluxing alloys

- Ceramic spray powders

Application:

- Premium coating system for aircraft turbines

- Components for textile machines, pulp- and paper machines and printing machines

- Hydraulic engineering

Triplex pro plasma spraying

Advantages:

- 3 Cathode technology with 3 independent arcs

- Stable High throughput increases productivity

- plasma arc across a wide range of gas flows, gas mixtures, and pressures

- Sprays all types of powder materials

- Thick and dense layers

- Stable and reproducible results

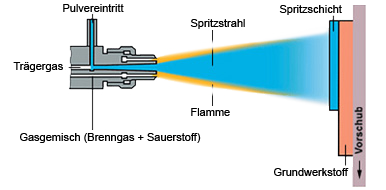

Powder flame spraying

Powder flame spraying Characteristics:

- All-purpose, cost effective spraying technology (UNI-SPRAY-JET/ MINI-SPRAY-JET)

- Only filler material in powder form usable

Advantages:

- Almost all filler materials, including ceramics processible

- No air pressure needed

- Low investment costs

Application :

- Repair coatings

- Protection against corrosion

- Wear protection

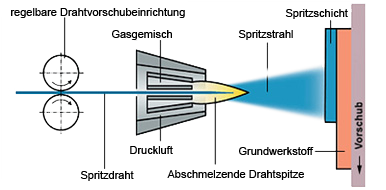

Wire flame spraying

Wire flame spraying Characteristics:

- Cost-effective spraying technology for the manufacture of metallic coatings

- Only filler material in wire form usable

Advantages::

- All sprayed particles are melted thoroughly

- High deposition efficiency

Spraying materials:

- Miscellaneous carbon-, chrome- and chromium-nickel steels, bronze, zinc, copper, molybdenum, nickel and aluminum-nickel etc.

Application:

- Repair of worn out machines

- Protection against corrosion

- Wear protection with molybdenum

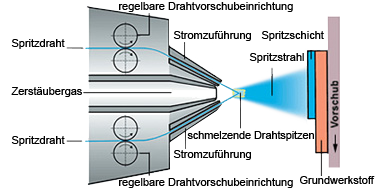

Arc spraying

Arc spraying Characteristics:

- Spraying technology with high deposition rate

- Only spraying material in wire form usable

Advantages :

- High melting: up to > 20kg/h

- High adhesion

- Low operating expenses

- Very rough coatings producible

Application :

- Repair and wear protection

- Protection against corrosion for bigger components or thick coatings > 1.0mm