Kinetic and thermal energy

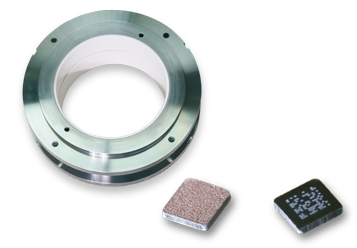

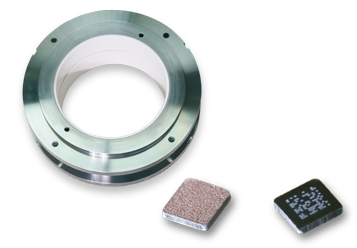

In various applications

Cold spraying and thermal spraying are both based around the application of kinetic and thermal energy, but their basic processes differ. Cold spraying avoids oxidization of the coating material, by using a much lower process temperature (150 - 800°C). This allows the creation of coatings with very good electrical and thermal conductivity. The cold spray process can also create excellent induction coatings and solderable coatings.

Thermal spraying has a near-universal range of materials and applications, and can create coatings suitable for many different industrial sectors.

Thermal spraying has a near-universal range of materials and applications, and can create coatings suitable for many different industrial sectors.